Automated operation, real-time data visualization

In modern production environments, it is expected that each technological component can be operated in a maintenance-free, automated way, using as little human resources as possible.

As a consequence, even complex production systems are supervised by only a few specialists.

For larger halls, it is physically impossible for operators to go in and check several times a day that the production parameters for humidification or mist cooling are correct and that everything is working as expected.

Real-time information

Performance monitoring

Save production data

Self-diagnosis, alerts, possibility of remote intervention

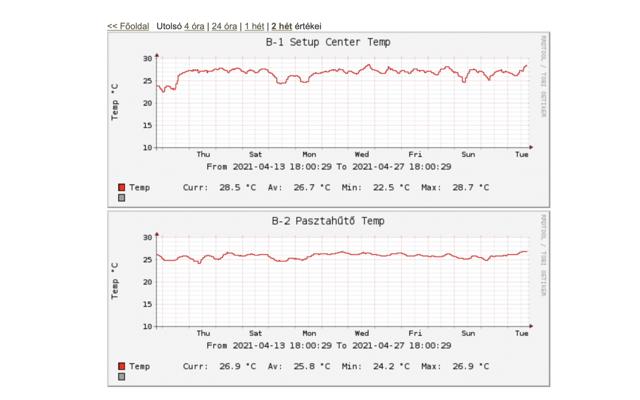

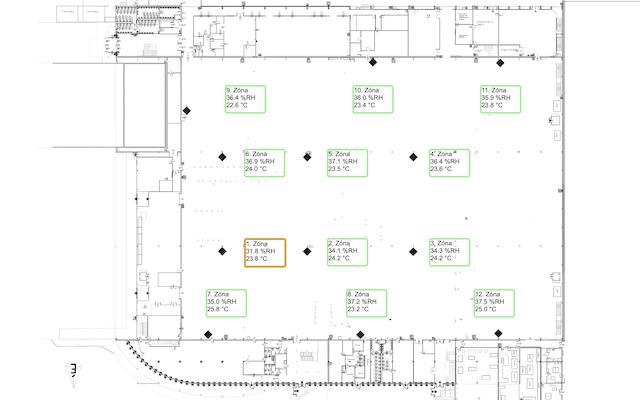

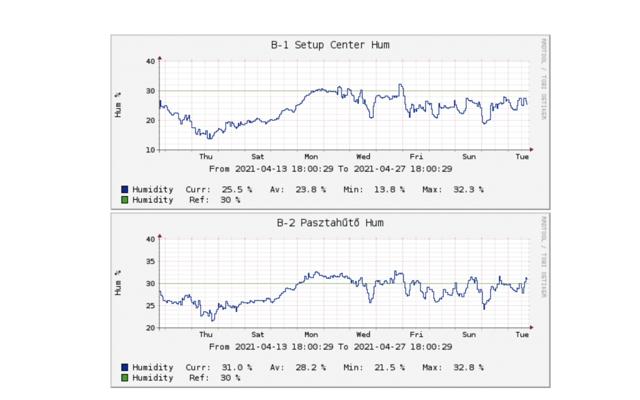

In our customers’ production halls, our systems measure specific environmental parameters (e.g. temperature, humidity, etc.) in dozens of locations, and automatically carry out the required interventions according to predefined boundary conditions.

The measured values used for control are periodically uploaded to a data processing server via a data acquisition system installed by DITUSZ Ltd. Based on the data collected and processed on the server, the required values are continuously displayed via a web interface. With the help of a monitoring application, different alarm thresholds, alarm addresses and alarm profiles can be set for each measurement.

The system requires only a web browser and Internet access. Our systems also feature artificial intelligence-based failure prediction algorithms for certain key components. This greatly assists in the predictability of plant safety, maintenance requirements and ultimately the sustainability of production continuity.

Along with real-time graphical monitoring and advanced alarm protocols, our equipment is also capable of some level of self-diagnostics and incident prediction.

Benefits :

+ Graphical display of real-time process values

+ Threshold monitoring

+ Operational performance monitoring

+ Zone level status indication

+ Possibility of remote intervention

+ Preventive maintenance

+ Indication of maintenance tasks due

Ask our colleague!